Table of Contents

The High Cost of Downtime in Industrial Inspection

Unplanned downtime is expensive. Every extra hour spent troubleshooting equipment, repeating scans, or waiting on reports compounds labor costs, schedule pressure, and risk exposure. Safety slips when processes slow—teams take shortcuts, cranes keep running, and assets stay offline longer than planned. Reducing downtime is ultimately a safety strategy, and vice versa. That’s why ScanTech’s approach combines rugged hardware, patent-backed mechanisms, and inspection software designed to deliver clear results fast.

Common Causes of Downtime & Risk in Inspections

Manual limitations slow data and raise exposure

Manual scanning introduces inconsistency: variable probe pressure, uneven coverage, and human fatigue. Rework and rescans follow, extending time on asset and increasing potential exposure.

Harsh environments demand specialized designs

Heat, dust, coatings, geometry changes, and overhead or vertical surfaces all challenge reliable coupling and encoder accuracy. Generic hardware often fails in these conditions, forcing stoppages and compromises.

Fragmented workflows delay decisions

When data capture and analysis live in different worlds, insights lag behind acquisition. Exporting files, performing manual calculations, and formatting reports can add hours or days—time assets remain out of service.

How ScanTech’s Patent-Backed Designs Prevent Failures

Mechanisms engineered for real-world surfaces

ScanTech’s surface-following assemblies and kinematics are designed to maintain consistent coupling on varied geometries—pipes, tanks, and vessels—limiting the tipping moments and misalignment that commonly cause bad data and rescans. These innovations protect data quality even when conditions are far from clean room-ideal.

Purpose-built motion and encoding

Drive systems, truck geometry, and encoder placement are engineered to keep traction and track length accurate on vertical, inverted, and coated surfaces. Better traction and true distance equal fewer voids in coverage and fewer repeats.

Learn more about the engineering approach in ScanTech News (patent-backed design features and product development insights).

Built For Safety: Rugged Housing, Modular Wheel Pack, Wireless Capabilities

Rugged builds for industrial duty

Scanner frames, carts, and housings use robust materials and sealed components to handle grit, moisture, and field shocks. Durable equipment resists unplanned stops and keeps the workflow predictable.

Modular Wheel Pack Assembly (WPA)

The Wheel Pack Assembly supports multiple configurations and payloads with strong pull force and stable tracking. Modularity allows rapid reconfiguration between methods and geometries—less time changing tools means more time scanning.

Cable-light, field-smart operation

Options that reduce tether complexity help minimize snags and trips, especially on elevated or congested sites. Cleaner routing and fewer connections translate into shorter setup and safer movement around the asset.

Real-World Examples Where Uptime Improves Safety

Corrosion mapping (C-scan) on complex piping

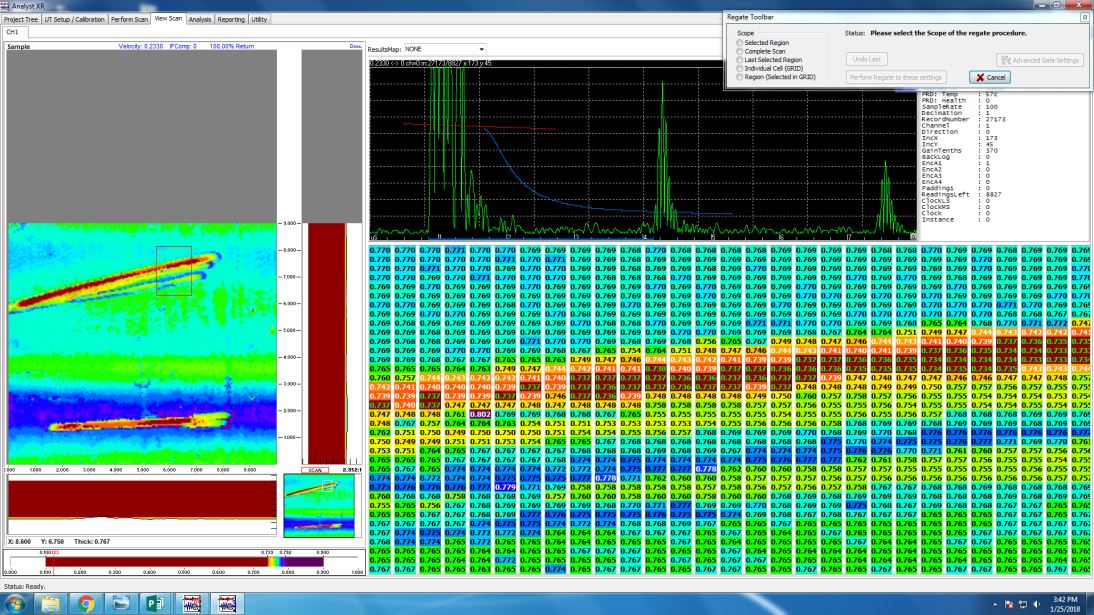

Corrosion mapping demands consistent coupling and precise encoder control. Platforms paired with Analyst XR streamline acquisition and interpretation for quicker decision cycles.

Internal links:

Tank inspection (B-scan) with rapid reporting

API 653 tank assessments benefit from B-scan thickness profiling and automated reporting. Analyst X generates structured outputs in seconds—less time between scan and decision reduces both downtime and on-asset exposure.

Internal links:

Modular platforms for multi-method efficiency

Systems like Apex and CLIX help inspection teams switch methods or diameter ranges without swapping entire scanners—cutting changeover time and avoiding re-rigging risks.

Internal links:

Safety and Uptime Start With The Right Scanner System

Faster, safer inspections are the outcome of three aligned elements: rugged scanners built for harsh sites, patent-backed mechanisms that keep coupling true, and software that turns signals into decisions quickly. The result is fewer rescans, clearer data, and shorter time on asset.

Explore the lineup and software ecosystem:

FAQs: Scanners Reduce Downtime

Q: What features most reduce rescans?

A: Stable coupling mechanisms, accurate encoders, and modular wheel packs reduce slippage and alignment errors—cutting rescans and keeping schedules on track.

Q: How does software impact safety and uptime?

A: Integrated algorithms (e.g., API 653, B31G) and streamlined workflows produce faster, more consistent outputs, shortening time to decision and limiting on-asset exposure.

Q: Which ScanTech platforms fit mixed-method work?

A: Apex and CLIX support multiple inspection methods and diameter ranges, reducing kit changes and setup time between jobs.